Note

Click here to download the full example code

PyMAPDL Tutorial#

In this tutorial, we will introduce some of the capabilities of PyMAPDL applied to Aerospace students and advocates.

Python + Ansys = PyAnsys#

PyAnsys is Ansys effort on making their products accessible using Python programming language.

Today we will focus on PyMAPDL with is the Python library which exposes MAPDL (Ansys Structural).

What is PyMAPDL?#

PyMAPDL is the pythonic interface for Ansys MAPDL product.

What does this mean?

It means that you can call Ansys MAPDL functionalities (Solvers, Post processing tools, etc) using Python programming language.

MAPDL provides many tools and features which would require A LOT of time to explain, so let’s have a quick overview.

Launching PyMAPDL#

But first, let’s launch PyMAPDL.

from ansys.mapdl.core import launch_mapdl

mapdl = launch_mapdl()

print(mapdl)

Product: Ansys Mechanical Enterprise

MAPDL Version: 22.2

ansys.mapdl Version: 0.63.2

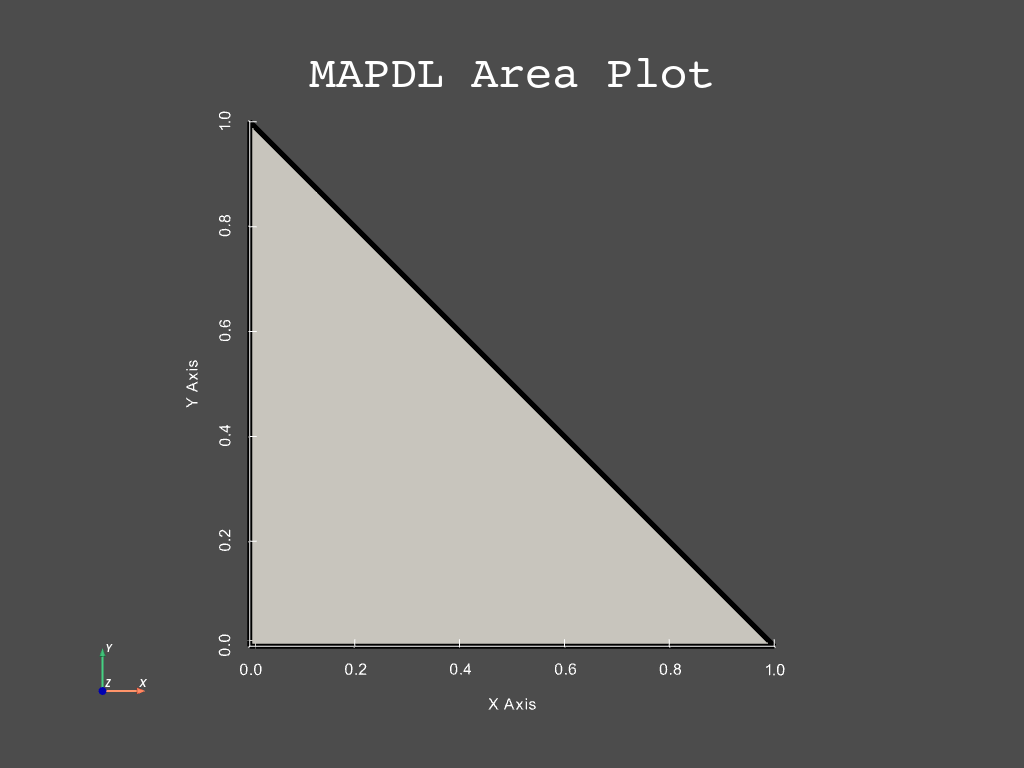

Geometry#

PyMAPDL support points (keypoints), lines, areas, and volumes for geometry definition.

You can plot an area using keypoints:

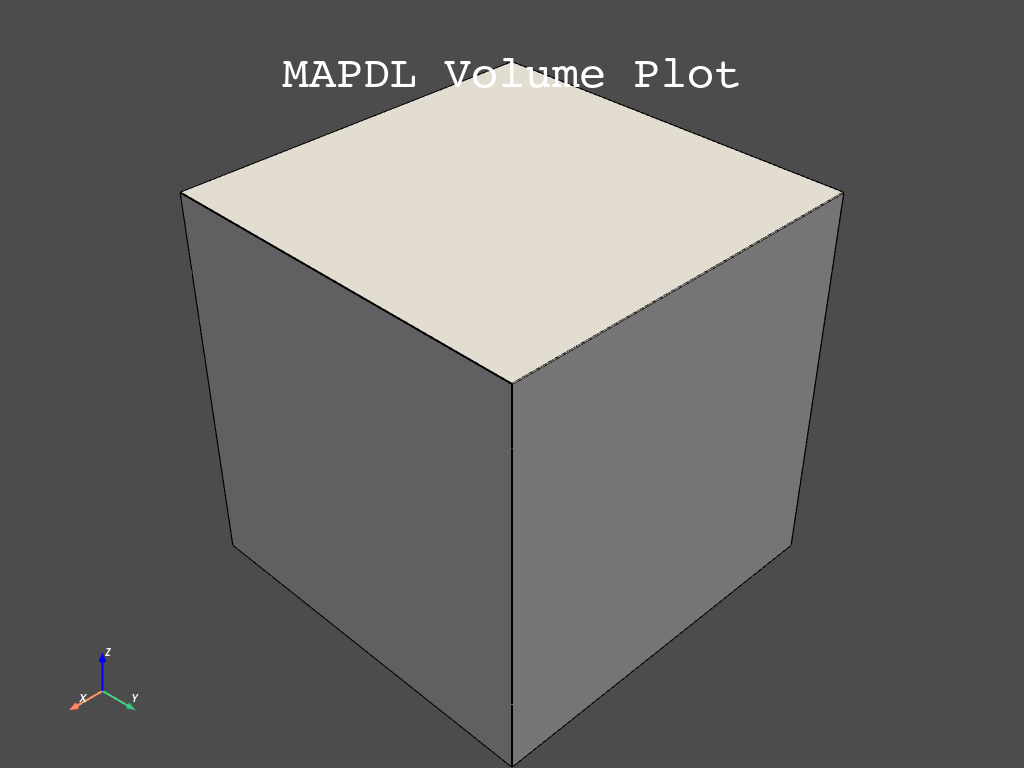

Create a simple cube volume.

mapdl.clear() # let's clear first.

mapdl.prep7() # entering in preprocessor

k0 = mapdl.k("", 0, 0, 0) # defining a keypoint at (0,0,0) location

k1 = mapdl.k("", 1, 0, 0) # defining a keypoint at (1,0,0) location

k2 = mapdl.k("", 1, 1, 0) # etc

k3 = mapdl.k("", 0, 1, 0)

k4 = mapdl.k("", 0, 0, 1)

k5 = mapdl.k("", 1, 0, 1)

k6 = mapdl.k("", 1, 1, 1)

k7 = mapdl.k("", 0, 1, 1)

# defining volume according the kps

v0 = mapdl.v(k0, k1, k2, k3, k4, k5, k6, k7)

mapdl.vplot(show_lines=True)

Material definition#

You can define materials using the following commands:

# Define a material (nominal steel in SI)

mapdl.mp("EX", 1, 210e9) # Elastic moduli in Pa (kg/(m*s**2))

mapdl.mp("DENS", 1, 7800) # Density in kg/m3

mapdl.mp("NUXY", 1, 0.3) # Poisson's Ratio

MATERIAL 1 NUXY = 0.3000000

At any point you can use help to get information about each function

help(mapdl.mp)

Help on method mp in module ansys.mapdl.core._commands.preproc.materials:

mp(lab='', mat='', c0='', c1='', c2='', c3='', c4='', **kwargs) method of ansys.mapdl.core.mapdl_grpc.MapdlGrpc instance

APDL Command: MP

Defines a linear material property as a constant or a function of

temperature.

Parameters

----------

lab

Valid material property label. Applicable labels are listed under

"Material Properties" in the input table for each element type in

the Element Reference. See Linear Material Properties in the

Material Reference for more complete property label definitions:

ALPD

Mass matrix multiplier for damping.

ALPX

Secant coefficients of thermal expansion (also ``ALPY``, ``ALPZ``).

BETD

Stiffness matrix multiplier for damping.

.. note:: If used in an explicit dynamic analysis, the value corresponds to the percentage of damping in the high

frequency domain. For example, 0.1 roughly corresponds to 10% damping in the high frequency domain.

BETX

Coefficient of diffusion expansion (also ``BETY``, ``BETZ``)

BVIS

Bulk viscosity

C

Specific heat

CREF

Reference concentration (may not be temperature dependent)

CSAT

Saturated concentration

CTEX

Instantaneous coefficients of thermal expansion (also ``CTEY``, ``CTEZ``)

CVH

Heat coefficient at constant volume per unit of mass

DENS

Mass density.

DMPR

Constant structural damping coefficient in full harmonic analysis or damping ratio in mode-superposition

analysis.

DXX

Diffusivity coefficients (also ``DYY``, ``DZZ``)

EMIS

Emissivity.

ENTH

Enthalpy.

EX

Elastic moduli (also ``EY``, ``EZ``)

GXY

Shear moduli (also ``GYZ``, ``GXZ``)

HF

Convection or film coefficient

KXX

Thermal conductivities (also ``KYY``, ``KZZ``)

LSST

Electric loss tangent

LSSM

Magnetic loss tangent

MGXX

Magnetic coercive forces (also ``MGYY``, ``MGZZ``)

MURX

Magnetic relative permeabilities (also ``MURY``, ``MURZ``)

MU

Coefficient of friction

NUXY

Minor Poisson's ratios (also ``NUYZ``, ``NUXZ``) (``NUXY`` = νyx, as described in Stress-Strain Relationships in the

Mechanical APDL Theory Reference)

PERX

Electric relative permittivities (also ``PERY``, ``PERZ``)

.. note:: If you enter permittivity values less than 1 for ``SOLID5``, ``PLANE13``, or ``SOLID98``, the program interprets

the values as absolute permittivity. Values input for ``PLANE223``, ``SOLID226``, or ``SOLID227`` are always interpreted as

relative permittivity.

PRXY

Major Poisson's ratios (also ``PRYZ``, ``PRXZ``) (``PRXY`` = νxy, as described in Stress-

Strain Relationships in the Mechanical APDL Theory

Reference)

QRATE

Heat generation rate for thermal mass element MASS71. Fraction of plastic work

converted to heat (Taylor-Quinney coefficient) for coupled-

field elements ``PLANE223``, ``SOLID226``, and ``SOLID227``.

REFT

Reference temperature. Must be defined as a constant; ``C1`` through ``C4`` are

ignored.

RH

Hall Coefficient.

RSVX

Electrical resistivities (also ``RSVY``, ``RSVZ``).

SBKX

Seebeck coefficients (also ``SBKY``, ``SBKZ``).

SONC

Sonic velocity.

THSX

Thermal strain (also ``THSY``, ``THSZ``).

VISC

Viscosity.

mat

Material reference number to be associated with the elements

(defaults to the current MAT setting [MAT]).

c0

Material property value, or if a property-versus-temperature

polynomial is being defined, the constant term in the polynomial.

``C0`` can also be a table name (``%tabname%``); if ``C0`` is a table name, ``C1``

through ``C4`` are ignored.

c1, c2, c3, c4

Coefficients of the linear, quadratic, cubic, and quartic terms,

respectively, in the property-versus-temperature polynomial. Leave

blank (or set to zero) for a constant material property.

Notes

-----

MP defines a linear material property as a constant or in terms of a

fourth order polynomial as a function of temperature. (See the TB

command for nonlinear material property input.) Linear material

properties typically require a single substep for solution, whereas

nonlinear material properties require multiple substeps; see Linear

Material Properties in the Material Reference for details.

If the constants ``C1`` - ``C4`` are input, the polynomial

.. math::

Property = C_0 + C_1(T) + C_2(T)^2 + C_3(T)^3 + C_4(T)^4

is evaluated at discrete temperature points with linear interpolation

between points (that is, a piecewise linear representation) and a

constant-valued extrapolation beyond the extreme points. First-order

properties use two discrete points (±9999°).

The :meth:`MPTEMP <ansys.mapdl.core.Mapdl.mptemp>` or

:meth:`MPTGEN <ansys.mapdl.core.Mapdl.mptgen>`

commands must be used for second and higher order properties to define

appropriate temperature steps. To ensure that the number of

temperatures defined via the :meth:`MPTEMP <ansys.mapdl.core.Mapdl.mptemp>`

and :meth:`MPTGEN <ansys.mapdl.core.Mapdl.mptgen>` commands is minimally

sufficient for a reasonable representation of the curve, ANSYS

generates an error message if the number is less than ``N``, and a warning

message if the number is less than ``2N``. The value ``N`` represents the

highest coefficient used; for example, if ``C3`` is nonzero and ``C4`` is zero,

a cubic curve is being used which is defined using 4 coefficients so

that ``N`` = 4.

Or you can check the online help at mapdl.docs.pyansys.com

Element definition#

Since MAPDL is a finite element solver, the type of element needs to be defined. Ansys has an Element Guide which contain all the necessary information

mapdl.et(1, "SOLID186")

1

SOLID186 is a 3D hexahedron element, suitable for

any structural 3D analysis.

There are also KEYOPTS which allow us to

configure the elements.

Also there is the constant sets R which helps

us to set the analysis and element configurations.

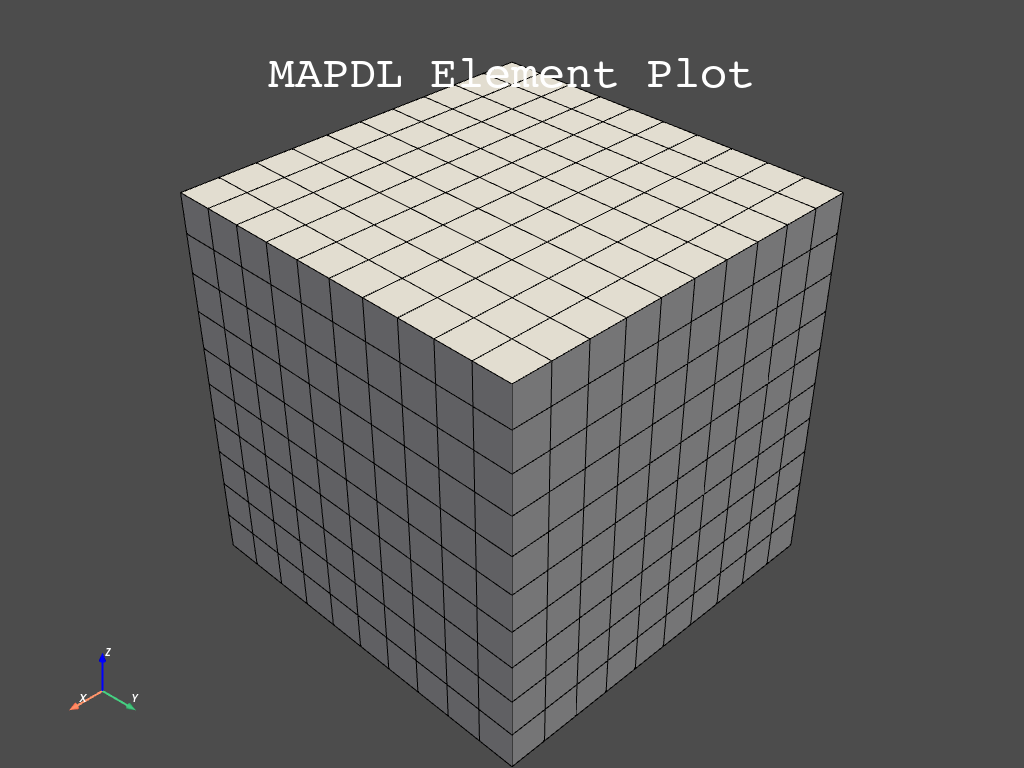

Meshing#

Meshing is quite easy, once the element and material are defined.

mapdl.esize(1 / 10) # Element size

mapdl.vmesh(v0)

GENERATE NODES AND ELEMENTS

IN VOLUMES 1 TO 1 IN STEPS OF 1

NUMBER OF VOLUMES MESHED = 1

MAXIMUM NODE NUMBER = 4961

MAXIMUM ELEMENT NUMBER = 1000

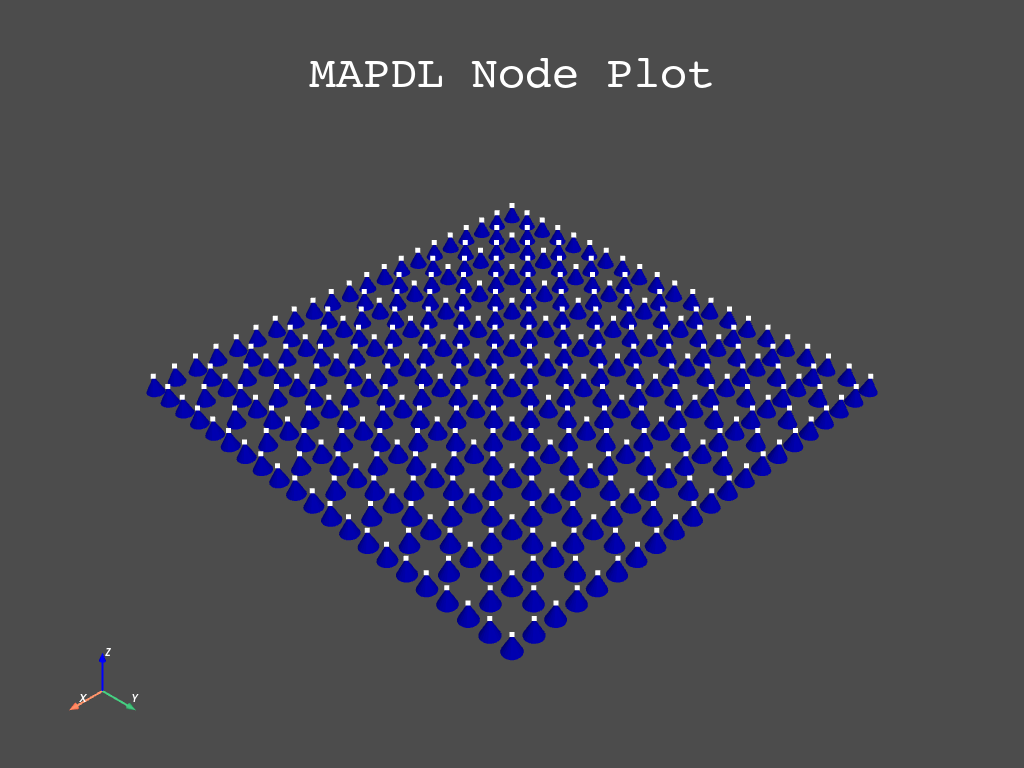

Let’s see the result

mapdl.eplot() # plot elements

Boundary conditions#

There are many boundary conditions options, and most of

them are applied using mapdl.d (for displacement)

or mapdl.f (for force).

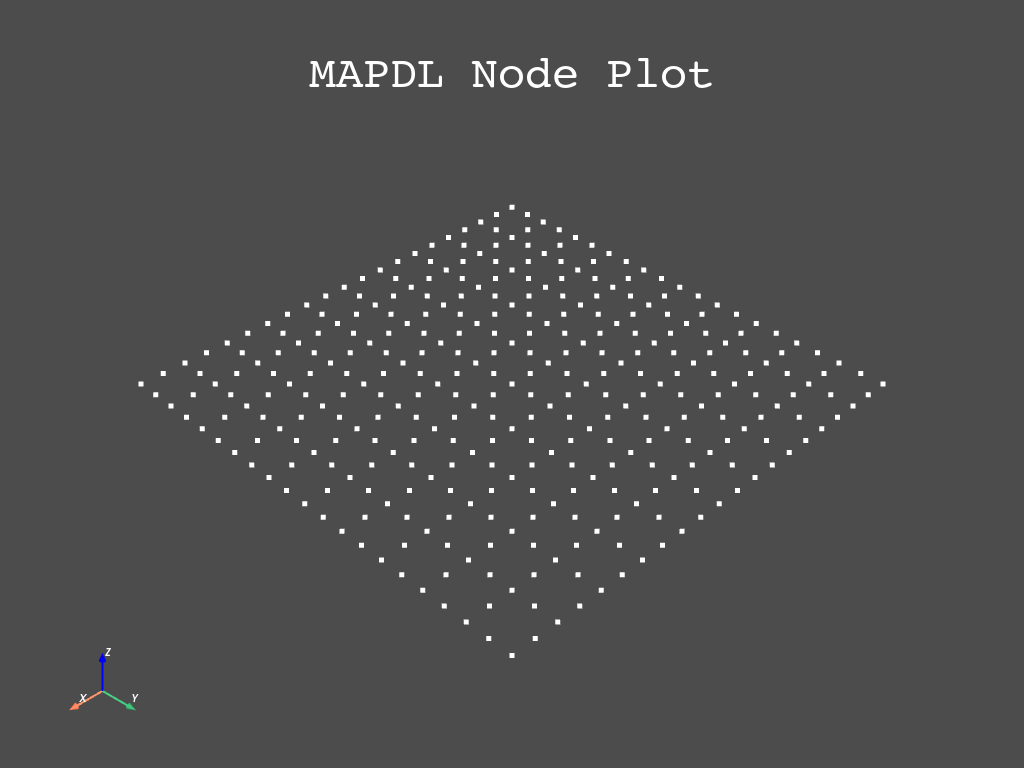

Let’s setup this example to represent a compression test. For that purpose, we need to fix the box bottom surface to have zero displacement.

But first, we need to select the corresponding nodes using

the mapdl.nsel command:

help(mapdl.nsel)

Help on method nsel in module ansys.mapdl.core._commands.database.selecting:

nsel(type_='', item='', comp='', vmin='', vmax='', vinc='', kabs='', **kwargs) method of ansys.mapdl.core.mapdl_grpc.MapdlGrpc instance

Selects a subset of nodes.

APDL Command: NSEL

Parameters

----------

type\_

Label identifying the type of select:

S - Select a new set (default).

R - Reselect a set from the current set.

A - Additionally select a set and extend the current set.

U - Unselect a set from the current set.

ALL - Restore the full set.

NONE - Unselect the full set.

INVE - Invert the current set (selected becomes unselected and vice versa).

STAT - Display the current select status.

The following fields are used only with Type = S, R, A, or U:

Item

Label identifying data. Valid item labels are shown in the table below. Some items also require a

component label. If Item = PICK (or simply "P"), graphical picking is enabled and all remaining

command fields are ignored (valid only in the GUI). Defaults to NODE.

Comp

Component of the item (if required). Valid component labels are shown in the table below.

VMIN

Minimum value of item range. Ranges are node numbers, set numbers, coordinate values, load

values, or result values as appropriate for the item. A component name (as specified on the CM (p. 338)

command) may also be substituted for VMIN (VMAX and VINC are ignored).

VMAX

Maximum value of item range. VMAX defaults to VMIN for input values. For result values, VMAX

defaults to infinity if VMIN is positive, or to zero if VMIN is negative.

VINC

Value increment within range. Used only with integer ranges (such as for node and set numbers).

Defaults to 1. VINC cannot be negative.

KABS

Absolute value key:

- `kabs = 0` - Check sign of value during selection.

- `kabs = 1` - Use absolute value during selection (sign ignored)

Notes

-----

Selects a subset of nodes. For example, to select a new set of nodes

based on node numbers 1 through 7, do

>>> mapdl.nsel('S','NODE','',1,7)

The subset is used when the `'ALL'` label is entered (or implied)

on other commands, such as

>>> mapdl.nlist('ALL')

Only data identified by node number are selected. Data

are flagged as selected and unselected; no data are actually deleted

from the database.

When selecting nodes by results, the full graphics value is used,

regardless of whether PowerGraphics is on.

Solution result data consists of two types, 1) nodal degree of freedom

--results initially calculated at the nodes (such as displacement,

temperature, pressure, etc.), and 2) element--results initially

calculated elsewhere (such as at an element integration point or

thickness location) and then recalculated at the nodes (such as

stresses, strains, etc.). Various element results also depend upon the

recalculation method and the selected results location [AVPRIN, RSYS,

FORCE, LAYER and SHELL].

You must have all the nodes (corner and midside nodes) on the external

face of the element selected to use Item = EXT.

This command is valid in any processor.

For Selects based on non-integer numbers (coordinates, results, etc.),

items that are within the range VMIN-Toler and VMAX+Toler are selected.

The default tolerance Toler is based on the relative values of VMIN and

VMAX as follows:

If VMIN = VMAX, Toler = 0.005 x VMIN.

If VMIN = VMAX = 0.0, Toler = 1.0E-6.

If VMAX ≠ VMIN, Toler = 1.0E-8 x (VMAX-VMIN).

Use the SELTOL command to override this default and specify Toler

explicitly.

Table: 208:: : NSEL - Valid Item and Component Labels

Table: 209:: : NSEL - Valid Item and Component Labels for Nodal DOF

Result Values

Examples

--------

Select nodes at `x == 0`, Of these, reselect nodes between ``1 < Y

< 10``, then finally unselect nodes between ``5 < Y < 6``.

>>> mapdl.nsel('S', 'LOC', 'X', 0)

>>> mapdl.nsel('R', 'LOC', 'Y', 1, 10)

>>> mapdl.nsel('U', 'LOC', 'Y', 5, 6)

For other coordinate systems activate the coord system first.

First, change to cylindrical coordinate system, select nodes at

``radius == 5``. Reselect nodes from 0 to 90 degrees.

>>> mapdl.csys(1)

>>> mapdl.nsel('S', 'LOC', 'X', 5)

>>> mapdl.nsel('R', 'LOC', 'Y', 0, 90)

Note that the labels X, Y, and Z are always used, regardless of which

coordinate system is activated. They take on different meanings in

different systems Additionally, angles are always in degrees and

NOT radians.

Select elements assigned to material property 2

>>> mapdl.esel('S', 'MAT', '', 2)

Select the nodes these elements use

>>> mapdl.nsle()

Reselect nodes on the element external surfaces

>>> mapdl.nsel('R', 'EXT')

Change to cylindrical coordinates

>>> mapdl.csys(1)

Reselect nodes with radius=5

>>> mapdl.nsel('R', 'LOC', 'X', 5)

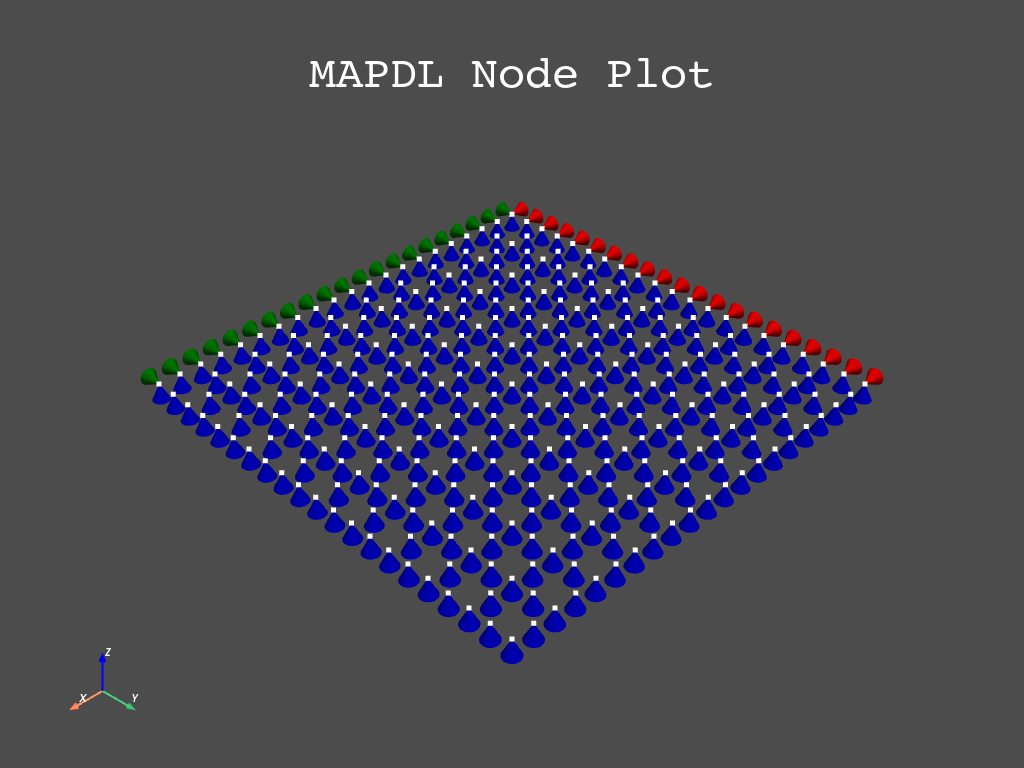

mapdl.nsel("S", "loc", "z", 0)

mapdl.nplot() # check the selection

Applying to all selected nodes, displacement in Z direction equals to zero.

mapdl.d("all", "UZ", 0)

# Let's check the result

mapdl.nplot(plot_bc=True)

Let’s apply the rest of the boundary conditions.

# Let's fix the box edge XZ to not move except along Y.

mapdl.nsel("s", "loc", "z", 0)

# "r" is to reselect the nodes, from the previous "S" selection

mapdl.nsel("r", "loc", "x", 0)

mapdl.d("all", "UZ", 0)

mapdl.d("all", "UX", 0)

# we will do the same with the line YZ, but not move along X direction.

mapdl.nsel("s", "loc", "z", 0)

mapdl.nsel("r", "loc", "Y", 0)

mapdl.d("all", "UZ", 0)

mapdl.d("all", "UY", 0)

SPECIFIED CONSTRAINT UY FOR SELECTED NODES 1 TO 4961 BY 1

REAL= 0.00000000 IMAG= 0.00000000

Finally let’s fix one node in the directions:

mapdl.nsel("s", "loc", "x", 0)

mapdl.nsel("r", "loc", "y", 0)

mapdl.nsel("r", "loc", "z", 0)

mapdl.d("all", "all", 0)

# this code is redundant, because the nodal displacements do not overwrite each other

# if they are not in the same direction.

# This node was included in the previous lines selections, hence its

# boundary conditions are already defined.

SPECIFIED CONSTRAINT UX FOR SELECTED NODES 1 TO 4961 BY 1

REAL= 0.00000000 IMAG= 0.00000000

ADDITIONAL DOFS= UY UZ

Let’s check the final result

mapdl.nsel("s", "loc", "z", 0)

mapdl.nplot(plot_bc=True)

Now let’s apply a displacement at the box top at each node. We could apply a force instead if we wish.

mapdl.nsel("s", "loc", "z", 1)

# mapdl.f("all", "FZ", 1E9)

mapdl.d("all", "UZ", 0.01)

SPECIFIED CONSTRAINT UZ FOR SELECTED NODES 1 TO 4961 BY 1

REAL= 1.000000000E-02 IMAG= 0.00000000

Analysis setup#

Let’s do a simple static analysis

mapdl.slashsolu()

mapdl.allsel() # making sure all nodes and elements are selected.

mapdl.antype("STATIC")

output = mapdl.solve()

print(output)

***** MAPDL SOLVE COMMAND *****

*** NOTE *** CP = 1.569 TIME= 10:48:46

There is no title defined for this analysis.

*** SELECTION OF ELEMENT TECHNOLOGIES FOR APPLICABLE ELEMENTS ***

---GIVE SUGGESTIONS ONLY---

ELEMENT TYPE 1 IS SOLID186. KEYOPT(2) IS ALREADY SET AS SUGGESTED.

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 22.2 ***

Ansys Mechanical Enterprise

00000000 VERSION=LINUX x64 10:48:46 OCT 03, 2022 CP= 1.582

S O L U T I O N O P T I O N S

PROBLEM DIMENSIONALITY. . . . . . . . . . . . .3-D

DEGREES OF FREEDOM. . . . . . UX UY UZ

ANALYSIS TYPE . . . . . . . . . . . . . . . . .STATIC (STEADY-STATE)

GLOBALLY ASSEMBLED MATRIX . . . . . . . . . . .SYMMETRIC

*** NOTE *** CP = 1.586 TIME= 10:48:46

Present time 0 is less than or equal to the previous time. Time will

default to 1.

*** NOTE *** CP = 1.590 TIME= 10:48:46

The conditions for direct assembly have been met. No .emat or .erot

files will be produced.

L O A D S T E P O P T I O N S

LOAD STEP NUMBER. . . . . . . . . . . . . . . . 1

TIME AT END OF THE LOAD STEP. . . . . . . . . . 1.0000

NUMBER OF SUBSTEPS. . . . . . . . . . . . . . . 1

STEP CHANGE BOUNDARY CONDITIONS . . . . . . . . NO

PRINT OUTPUT CONTROLS . . . . . . . . . . . . .NO PRINTOUT

DATABASE OUTPUT CONTROLS. . . . . . . . . . . .ALL DATA WRITTEN

FOR THE LAST SUBSTEP

SOLUTION MONITORING INFO IS WRITTEN TO FILE= file.mntr

*********** PRECISE MASS SUMMARY ***********

TOTAL RIGID BODY MASS MATRIX ABOUT ORIGIN

Translational mass | Coupled translational/rotational mass

7800.0 0.0000 0.0000 | 0.0000 3900.0 -3900.0

0.0000 7800.0 0.0000 | -3900.0 0.0000 3900.0

0.0000 0.0000 7800.0 | 3900.0 -3900.0 0.0000

------------------------------------------ | ------------------------------------------

| Rotational mass (inertia)

| 5200.0 -1950.0 -1950.0

| -1950.0 5200.0 -1950.0

| -1950.0 -1950.0 5200.0

TOTAL MASS = 7800.0

The mass principal axes coincide with the global Cartesian axes

CENTER OF MASS (X,Y,Z)= 0.50000 0.50000 0.50000

TOTAL INERTIA ABOUT CENTER OF MASS

1300.0 -0.41069E-11 -0.16058E-11

-0.41069E-11 1300.0 -0.72902E-11

-0.16058E-11 -0.72902E-11 1300.0

The inertia principal axes coincide with the global Cartesian axes

*** MASS SUMMARY BY ELEMENT TYPE ***

TYPE MASS

1 7800.00

Range of element maximum matrix coefficients in global coordinates

Maximum = 1.914529915E+10 at element 247.

Minimum = 1.914529915E+10 at element 556.

*** ELEMENT MATRIX FORMULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 1000 SOLID186 0.303 0.000303

Time at end of element matrix formulation CP = 1.86823082.

SPARSE MATRIX DIRECT SOLVER.

Number of equations = 14159, Maximum wavefront = 225

Memory allocated for solver = 113.349 MB

Memory required for in-core solution = 108.776 MB

Memory required for out-of-core solution = 44.000 MB

*** NOTE *** CP = 2.170 TIME= 10:48:46

The Sparse Matrix Solver is currently running in the in-core memory

mode. This memory mode uses the most amount of memory in order to

avoid using the hard drive as much as possible, which most often

results in the fastest solution time. This mode is recommended if

enough physical memory is present to accommodate all of the solver

data.

Sparse solver maximum pivot= 7.658119658E+10 at node 4420 UY.

Sparse solver minimum pivot= 4.423964031E+09 at node 672 UZ.

Sparse solver minimum pivot in absolute value= 4.423964031E+09 at node

672 UZ.

*** ELEMENT RESULT CALCULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 1000 SOLID186 0.225 0.000225

*** NODAL LOAD CALCULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 1000 SOLID186 0.045 0.000045

*** LOAD STEP 1 SUBSTEP 1 COMPLETED. CUM ITER = 1

*** TIME = 1.00000 TIME INC = 1.00000 NEW TRIANG MATRIX

*** MAPDL BINARY FILE STATISTICS

BUFFER SIZE USED= 16384

10.250 MB WRITTEN ON ASSEMBLED MATRIX FILE: file.full

1.750 MB WRITTEN ON RESULTS FILE: file.rst

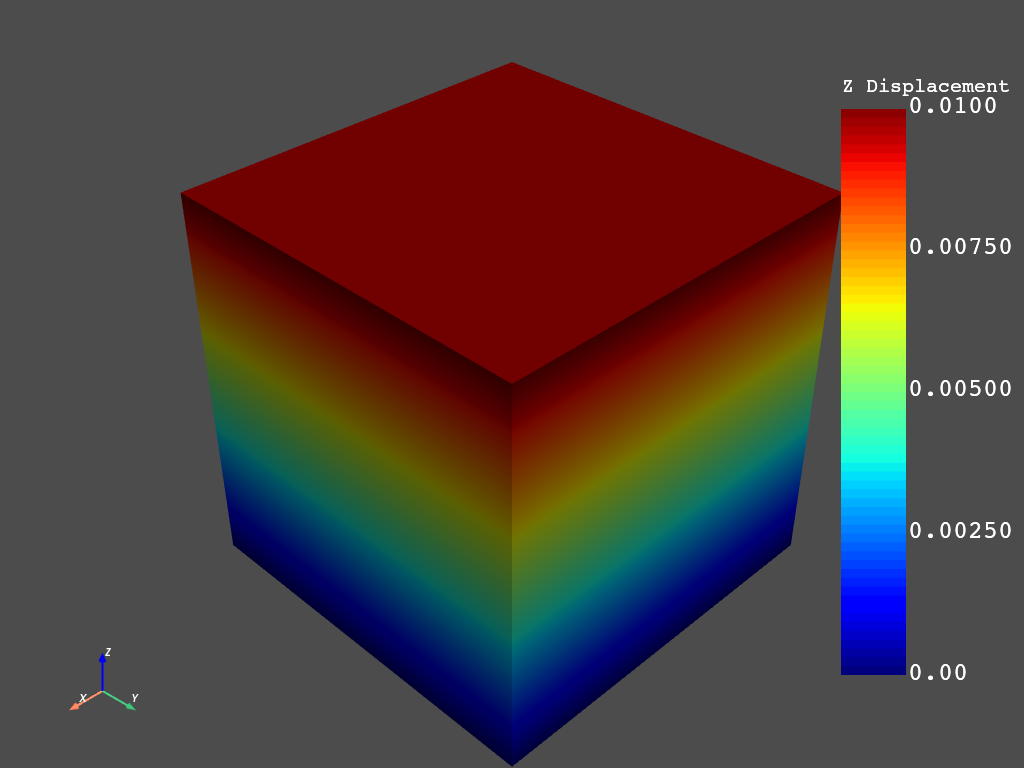

Post-Processing#

Let’s what we got. Let’s see the displacements:

mapdl.post_processing.nodal_displacement("all")

array([[ 0. , 0. , 0. ],

[-0.003 , 0. , 0. ],

[-0.00015, 0. , 0. ],

...,

[-0.00285, -0.0027 , 0.007 ],

[-0.00285, -0.0027 , 0.008 ],

[-0.00285, -0.0027 , 0.009 ]])

Let’s plot them

mapdl.post_processing.plot_nodal_displacement("Z")

We can store the displacements as an array and use them for our calculations. For example:

nodal_disp = mapdl.post_processing.nodal_displacement("all")

print(f"The maximum displacement is {nodal_disp.max():0.3f}")

The maximum displacement is 0.010

Oh! By the way, you can format strings in this way, they are very powerful. This type of string is called f-string. The 0.3f after the colon (:) is the format for the number.

# First column is X displacement

print(f"The maximum X displacement is {nodal_disp[:, 0].max():0.3f}")

print(f"The average Z displacement is {nodal_disp[:, 2].mean():0.3f}")

The maximum X displacement is 0.000

The average Z displacement is 0.005

Closing session#

This is all for today. We hope you enjoyed this talk, as much as we enjoyed preparing it!

Closing PyMAPDL session

mapdl.exit()

Total running time of the script: ( 0 minutes 6.266 seconds)